The undercarriage is one of the most expensive components on your crawler dozers. Knowing the life expectancy is essential to estimating the value of a used dozer or planning for a rebuild.

To get an example of how to do a thorough and accurate dozer undercarriage inspection, we went to John Deere dealer Flint Equipment in Atlanta, Georgia. There we asked Rodney Beavers, service manager, and Louie Leak, customer support adviser, to show us how to perform a thorough and accurate assessment of a dozer’s undercarriage wear. We shot video of the process which you can watch right here: Excavator Track Link

The process is fairly simple, but you’ll need to write down all your measurements and then compare them to the dealer or OEM recommended specs to get a percentage-of-wear figure for the whole undercarriage. You can buy the undercarriage measurement kit and do these measurements yourself or have the dealer do the measurements for you. Leak recommends taking measurements at least twice a year. Here are the steps:

To start with, look for any obvious problems, bent or damaged track pads or any structural damage. Our machine has rock guards covering most of the lower rollers, but the condition of the upper rollers should be an indication of how well the lower rollers are holding up. Look for any wetness or signs of oil leaking from the rollers and front idler.

A visual inspection will also tell you if the pins and bushings have been turned or need to be turned. If the top half of the bushing is worn, this means the pins and bushing have been turned. Finally, look at the teeth on the rear sprockets. If the teeth come to a sharp point, they’re worn down and will soon need to be replaced. As a rule of thumb, anytime you need to turn the pins and bushings, you likely also need to replace the sprocket teeth or vise-versa, says Beavers. Often the top rollers will need replacing at this point as well.

Measure the width of the shoes with a tape measure and the depth of the shoes with a depth gauge.

Use the caliper tool in the kit to measure the diameter of the top roller. Slide the tips of the caliper over the widest part of the roller and record the diameter. Look up that number on the OEM specs to get the percentage of wear.

Another set of calipers is used to measure the diameter of the bottom rollers, only this one has bent arms that allow you to slip it up underneath the flange shield to get the measurement.

Use the depth gauge again to measure the wear on the front idler.

Determine the pitch of the rail (the length or amount of stretch) by determining the distance between five pins, center to center, using a tape measure. Make sure the track is stretched tight by putting it in reverse and backing it up a few feet. That measurement will help you determine if the track has become “snaky” or moving side to side, which eventually will break the pins and the links.

On the underside of the track, put the horizontal bar on the depth gauge across the bottom of a rail segment and run the depth indicator post up to the bottom of the shoe to measure the wear on the rails.

After you’ve measured the rail height, use your pin and bushing calipers to measure the diameter of the bushing.

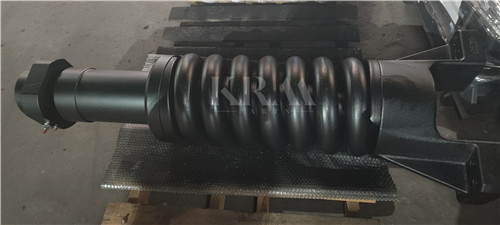

Aftermarket Excavator Track Chains Pull a straight edge across the shoes from the back roller to the front roller and measure how far down the track sags in the middle. You should try to keep about 2 ½ inches of sag. This ensures they are not too tight (which can accelerate wear) or too loose (which may cause the track to walk off).